The drone : For many years, Domaine Schlumberger has been fighting to obtain the use of drones in hillside vineyards, as our German, Swiss and Austrian neighbors do… Trials were carried out in 2021 and the finding is simple: the chaser projects the product upwards and produces a cloud while the drone flattens the product downwards and reduces the drift effect. The drone makes it possible to reduce fuel consumption, limit soil compaction and reduce employee exposure to products. It is perfectly adapted to organic cultivation. To date, we are still awaiting administrative decisions for its use!

Felt : Our estate is about to become one of the first Alsatian wineries to experiment with the use of felt blankets as an agroecological alternative to weeding under the row. Developed by Thorenap Vigne, these natural mulches are made from French hemp and recycled jute fiber. They are made without glue, binder or water, and are completely biodegradable after 3 years of ground coverage. In addition to weeding, the felts protect the surface soil from erosion and UV rays, limit water stress in the vines and reduce thermal variations.

Sound as protection : The estate has been experimenting with genodics in its vineyard for several years now. Genodics is a science developed in the 1980s by the French scientist Joël Sternheimer, whose idea is to help vine stocks resist diseases (esca, mildew, flavescence dorée, etc.), to adapt to climatic variations, and generally to strengthen their metabolism through the use of sound. An autonomous box with a radius of action of 10 to 15 hectares is placed in the vineyards and emits sounds whose frequencies stimulate the proteins of the vine with the aim of strengthening the plant in a 100% natural way, without any input.

Éco-design

In order to manage its waste treatment, the estate has signed an agreement with the town to sort waste, bring the fuel station and drinking water well up to standard, and recycle the label widths and pallets, which are 100% reused!

For many years now, the choice of bottle has been a light (440g, compared with the average 700g), brown bottle (which uses 70% recycled glass). Each bottle also features a 100% recyclable, plastic-free e-cap.

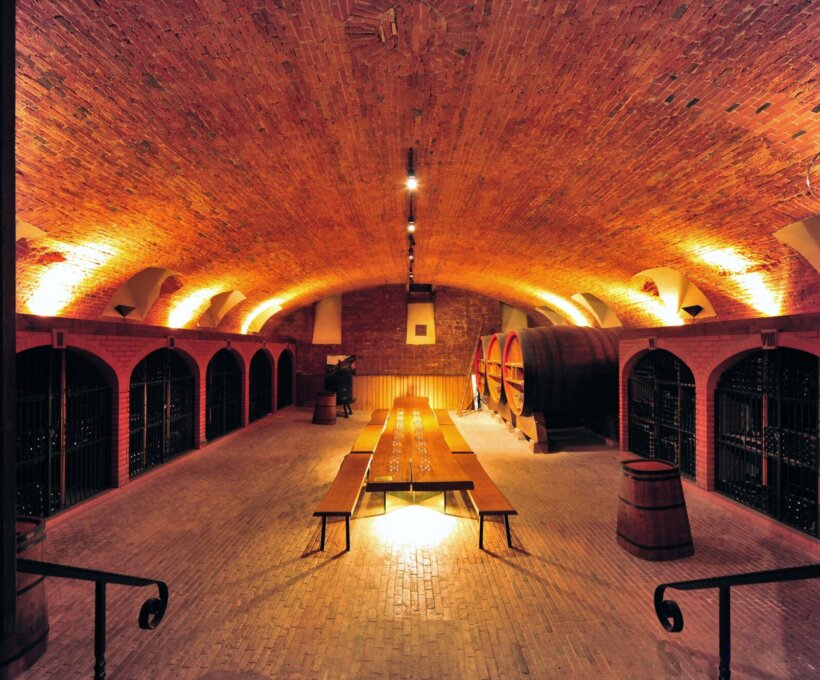

While storage is an important issue for winegrowers, we store around 800,000 bottles in a non-air-conditioned underground cellar. This is thanks to an ideal ambient temperature due to the presence of a stream of water in the cellar, which enables it to cool down. Finally, we carry out the labelling on site to take account of the requirements of customers in each country and to limit the waste of unused labels!